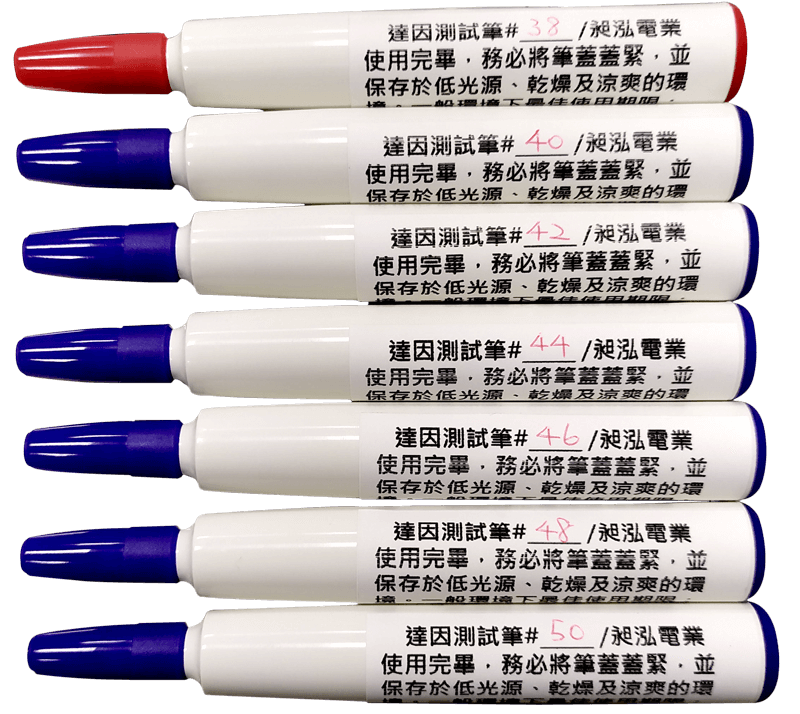

Corona test pen, also known as: dyne pen, the surface tension test pen, used to determine the plastic surface energy (surface tension) of the special ink document.

Provide dyne level (30, 32, 34, 36, 38, 40, 42, 44, 46, 48, 50, 52, 54, 56 ) "dyne / cm

Introduction of performance

Dyne test pen can accurately test the surface tension of plastic film whether the test pen level. So that users clearly understand this film is suitable for printing. Composite or aluminum vacuum. Effectively control the quality and reduce material failure by the tool caused by the delay. Chaang-Horng corona test pen, not limited to plastic, to test the surface tension of various materials.

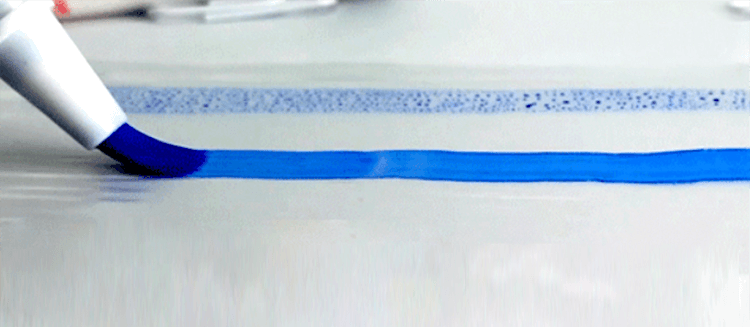

Test methods

In industrial practice, the plastic surface energy (surface tension) was measured by testing ink according to DIN ISO 8296, is known to different surface energy of ink in the film to be measured about 100mm long brush on the ink, and observe More than 90% of its ink edges in 2 seconds if the contraction and the formation of droplets, if any, are for low-level surface can be painted ink , for the same observation, until the drops do not shrink and the emergence of This test is the surface energy of ink corresponding to the film surface energy. This method can accurately measure the surface tension of the substrate surface before the wet strength and determination of work requirements to determine if the substrate surface in order to adjust the ink, coating, to the required viscosity. 30 to 56 mN / m 14 kinds of ink surface level of testing (each a difference 2mN / m). Corona document (38mN / m) can be used as corona treated surface can be a quick test tool, but not as well have been printed or coated surface of the system test. When the test pen corona treated surface to draw a line, if it is continuous into the line, indicating that the surface can not be less than 38mN / m, if not even into the line and off, indicating that the surface can not 38mN / m, deal with less or even untreated, the printing process does not meet requirements. Surface tension, surface force for the accurate determination of the wet printing ink and other materials on the surface of the bonding situation is very clear criteria, but there are other factors that affect the viscosity, such as static electricity, and many of the additives. However, these factors do not often shown in the test result, or even good results, but are deficient. This requires and raw material suppliers to discuss these technical issues. In general, the above will not happen to them, and that the surface value of 38-41mN / m that is able to achieve the viscosity required. The surface tension in 37mN / m below will cause many blank pages (no printing content), in 35mN / m below the viscosity on the bad.

Quality Assurance

- ISO / International Organization for Standardization (International Organization for Standardization)

- TAPPI / Technical Association of the Pulp and Paper Industry Technical Association of Pulp and Paper Industry [U.S.]

- ASTM / American Society of Testing Materials, ASTM